Subsea Cable Maintenance

Maintenance & Repair Expertise and Experience

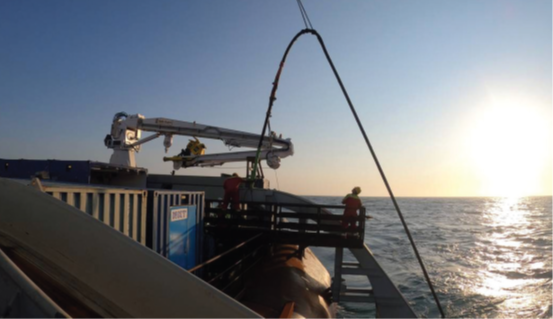

At Gulf Energy Technology & Projects marine division we provide submarine telecom cable maintenance services to around 121 maintenance authorities around the globe, with the primary aim of keeping our customers subsea fiber optic cable systems fully operational. Gulf Energy Technology & Projects marine division has unrivaled expertise and experience as well as an exceptional knowledge base with a commitment to advancing technological solutions, which means that we are a trusted and reliable partner of choice for organizations wanting to maximize the return on their cable system investment.

Expertise and Experience

It is our main objective to ensure that system downtime is minimized and that a broken segment of cable is repaired as quickly as possible, therefore Gulf Energy Technology & Projects marine division tries to mitigate the impact of these incidents by providing maintenance solutions that reflect each zones or customers individual requirements for quality, reliability, responsiveness, dependability, and speed of repair.

Benfits

• Repair, maintenance, and improvement of scheduled cables.

• Complete requirements for submarine telecommunications cable maintenance from beach joint to beach joint (but excluding shallow water and the beach joint itself –unless specifically contracted).

• Depot Services for supervised storage of system submersible spareplant and its testing.

• Universal Joint (UJ) jointing services.

• UJ & Cable Services, including cable qualification, training at our bespoke training school and the supply of innovative jointing solutions.

• Gulf Energy Technology & Projects marine division also provides additional offshore maintenance services as required, i.e. marine surveys, cable burial, shallow water repairs, cable and spare plant testing, offshore liaison and charting/system documentation management services.

UJ & Cable Services

Gulf Energy Technology & Projects marine division has an unrivalled depth of knowledge and experience in subsea cables from cable testing to the supply of Universal Joint and Universal Quick Joint parts, training, and qualification.

The Universal Joint (UJ) and the Universal Quick Joint (UQJ) provide anindustry recognized solution for the repair of fiber optic cable. It is essential that a cable is qualified so that appropriate tool kits can be prepared and to ensure its compatibility to the UJ or UQJ solution.

UJ Cable Qualification

Gulf Energy Technology & Projects marine division qualify cables to assess their suitability to work with Universal Joint technology. Each cable type is characterized, and bespoke piece parts are designed and manufactured.

Cable Testing & Test House

The joint containing the cable or cable combination is then rigorously tested to a common specification in the Test House to simulate shipboard deployment and requisite oceanographic conditions.

UJ & UQJ Jointing Kit & Jointing Toolkit Supply

Following success completion, a Qualification Certificate is issued to the customer and that cable (or cable combination) is included in the list of qualified cables and toolkits. End-specific kits and then constructed and manuals are produced.