Electrical LV/HV Motor Supply, Installation, Testing, Commissioning, Maintenance & Overhauling Work

- Supply, Installation, Testing & Maintenance of LV & HV Switchgears

- Testing, Commissioning & Condition Monitoring Services of Electrical Substation

- Transformer, OLTC Testing, Oil Leak Rectification, Oil filtration & Regeneration Work

- Electrical LV/HV Motor Supply, Installation, Testing, Commissioning, Maintenance & Overhauling Work

- Supply, Laying and Termination of Power Cables & FO cables

- Cable Fault Identification, Jointing and Testing Services

- Supply, Installation & Maintenance of Substation Equipment, UPS & Generator Systems

- Installation of Streetlights, High masts, Earthing & Lighting protection

Electrical LV/HV Motor Supply, Installation, Testing, Commissioning, Maintenance & Overhauling work

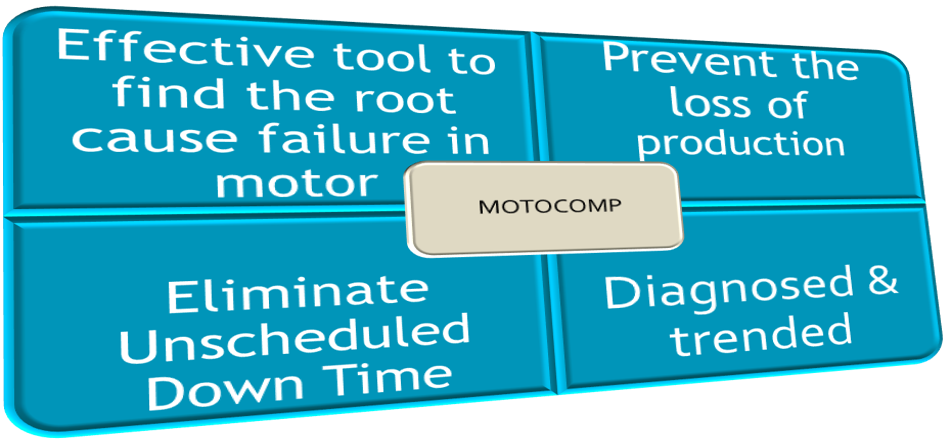

Electrical maintenance programs are designed to increase equipment promptness and uptime while decreasing capital operating cost. Electric Motor Testing is usually the first thing to be sacrificed when cutting back on operational expenses.

Bearing failure & electrical faults are the most common mode of motor failure, so in addition, a properly planned electrical testing scheme is important for making sure of the plant reliability. The 48% of motor failures are because of electrical failures. The 48% can be again divided into rotor problems (12%) and winding problems (36%). The other 52% of failures are mechanical faults.

Winding defects occurs due to contamination, ageing of insulation, thermal overload, power surges, damaged wire/materials, and other causes. They start as energy crossing an insulation fault like moisture, which sets apart at least one turn. This creates extra stress and increase in temperature across the fault, which increases until the winding fails.

Motor/Generator Testing (MotoLEP)

1. ONLINE TESTING

Electrical Signature Analysis (ESA/MCSA)Vibration & Acoustic Analysis

2. OFFLINE TESTING

Winding Resistance Measurement Insulation Resistance & Polarization Index Tan Delta & Capacitance Analysis Phase Resolved Partial Discharge AnalysisNon-linear Insulation behaviorPolarization & Depolarization Analysis

3. OVERHAULING & REPAIR

De-Coupling of Motor. Dismantling all removable cable of motors.Through cleaning of stator/rotor. Varnishing of Stator/rotor winding.Bearing replacement. Fitment of Motor.Assembly & Coupling of motors.

4.SUPPLY & INSTALLATION OF MOTOR & GENERATORS

Supply of low & high voltage motors from reputed brand (WEG Brazil) Installation, Testing & Commissioning of the Motor/Generator